Referanser

Her kan du se et lite utvalg av vårt arbeid.

Utstyr til nye SUS

På oppdrag for Riska Sveis har vi levert utstyr til en portal over innkjøringen til nye Stavanger Universitetssykehus som bygges på Ullanhaug. Portalen skal forhindre at for høye kjøretøy ikke kommer inn og skader gangbru. For best mulig beskyttelse til utstyrets bruk, har vi utført overflatebehandlingen Norsok system 2B, som er metallisering med zink.

Leveranser til elektrifiseringen av Edvard Grieg

Ferdige boilere klar for levering til Edvard Grieg feltet. Disse har blitt Metallisert etter våre egne prosedyrer, som er kontrollert og godkjent av sluttkunde for å oppfylle deres krav og spesifikasjoner. Nok en flott jobb utført av dyktige ansatte, der Jærsk kvalitet gjenspeiler seg.

Slangetromler og løfterammer

4 sett med slangetromler og løfterammer som har blitt overflatebehandlet etter Norsok M501 System 1.

Gjør moment trekking lettere med Xylan coating

For denne kunden har vi brukt Xylan type 1424, som er en vannbasert, harppiksbundet tørrfilm smøremiddel. Den er designet for å gi veldig god korrosjonsbeskyttelse generelt på Subsea utstyr. I tillegg er den mye brukt for å lettgjøre momenttrekking på bolter, mutrer etc.

Fra Jæren til Vest-Afrika

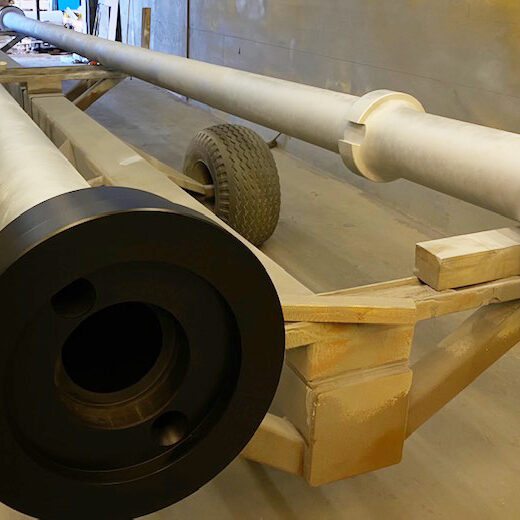

Nye riser produkter behandlet for vår kunde www.subseatec.se. Produktene er 15 meter lange, og vi har behandlet disse med svart Xylan coating i hele ID samt utvendig på flens. Resten av riserene har vi brukt metallisering ( TSA ) som overflatebehandling. Trykktesting og sluttkontroll vil bli utført av kunde, før levering til sluttdestinasjonen, som er…

Unihead

Bildet viser en komponent på 4,5T som kalles Unihead. Denne komponenten skal offshore og installeres i brønn. Den brukes til å henge og isolere forskjellige størrelser på foringsrør. Når brønnen er fullstendig boret og ferdigstilt, installeres et X-mass three på toppen av den, og produksjonen kan fortsette igjennom dette. Overflatebehandlingene som vi har utført på…

Leveranse til offshore og landbasert industri

Rammer og plate, produsert av Depro As, malt av oss i system for å tåle offshore belastninger. Rør konstruksjoner som skal frakte drikkevannet vårt. Disse er malt med en spesialmaling og prosedyre godkjent for drikkevannsystemer. Takknemlig for at vi får bidra med vår kompetanse!

Vanntanker for tunnelvasking

Norge er et av landene i verden med flest tunneler på veinettet, og hvert år bygges det kilometer med nye tunneler. Vask av tunneler minsker risikoen for ulykker og fører til økt trafikksikkerhet. Kjekt at vi får bidra med vår kompetanse på overflatebehandling.

IVAR vannbehandlingsanlegg Langevatn

IVAR vannbehandlingsanlegg Langevatn er det største anlegget i regionen. Anlegget som ble etablert i 1959, ligger i Gjesdal kommune og forsyner 11 IVAR-kommuner med drikkevann. Anlegget har kapasitet til å behandle 2500 liter vann i sekundet, og henter ubehandlet vann fra Romsvatn/Stølsvatn i Bjerkreim og Storavatn i Gjesdal. Vi i Jæren Overflatebehandling er både stolte…